Rolling Mills

Click on the product windows below to see expanded views of the many products the business supplies.

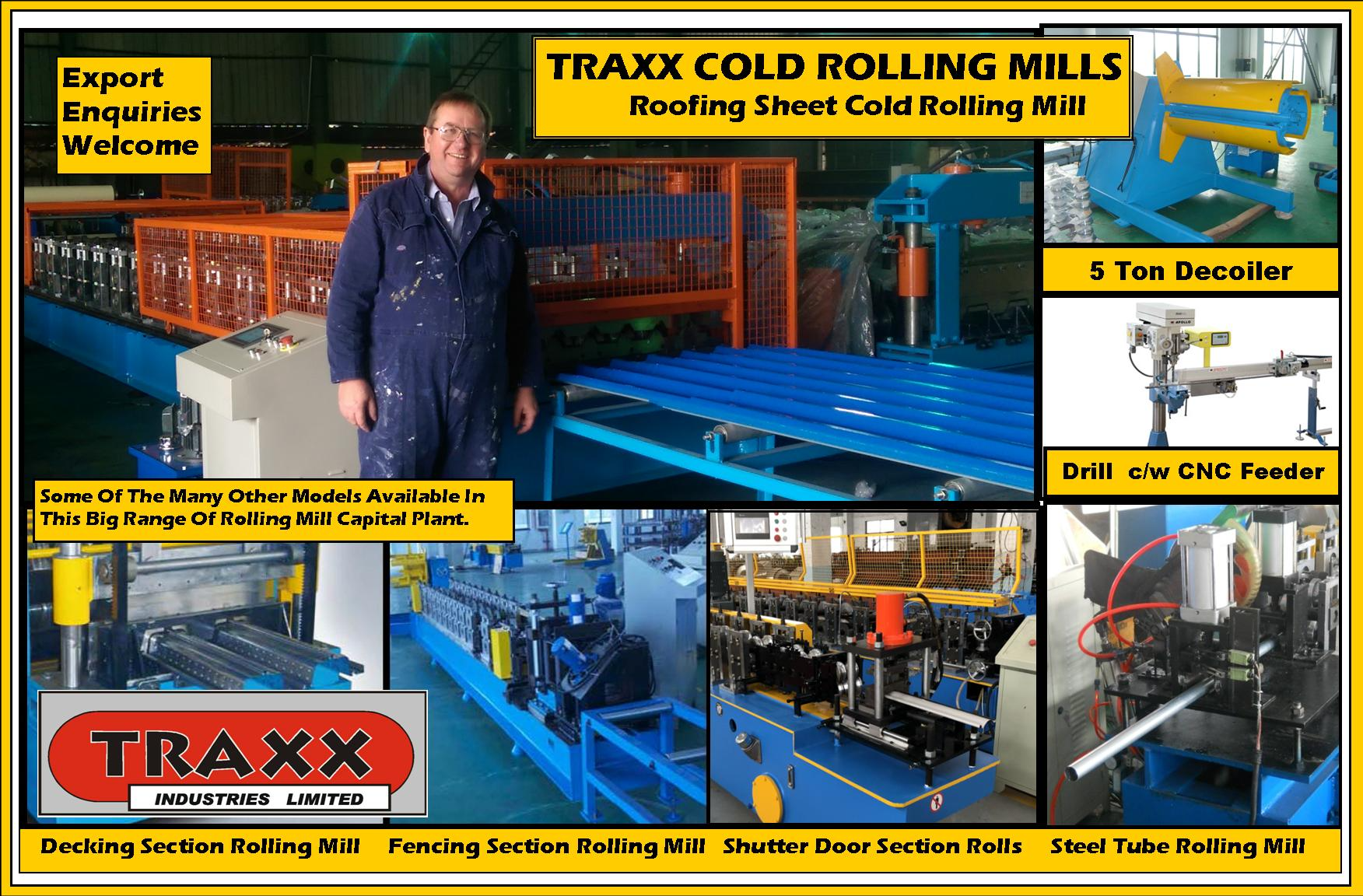

Traxx Industries Supply A Large Range of Rolling Mills, Tube Mills, Decoilers & Associated High Speed Punching Machine Lines

Contact Traxx Industries with your needs & let us show your business how to benefit as your business transforms with cold rolled section technologies and the associated plant we supply.

Looking for a quality vendor who can provide the necessary rolling mill capital plant for your project?

Get in touch with Haverhill based Traxx Industries Ltd.

We have a diverse range of plant and skills at our disposal needed to get the job done.

Call: 07963 851 455 or email us at mroberts892@btinternet.com

SOME OF THE MANY ROLLING MILL & ASSOCIATED CAPITAL PLANT EQUIPMENT SUPPLIED BY TRAXX:

Roofing Sheet Rolling Mills

As well as the roofing sheet rolling mills themselves we also supply –

A wide range of existing roofing sheet profile tooling for common trapezoidal

sections, cladding and the corrugated sections in existence.

Alternatively you can advise us of your own profile design and we can create

special tooling for your application using specialist software for the purpose.

Decking Section Rolling Mills

As well as providing the decking section rolling mills themselves we also supply –

A wide range range of existing profile tooling for existing decking sections in

existence.

Alternatively you advise us of your own profile design and we can create special tooling for

Your application using specialist software for this purpose.

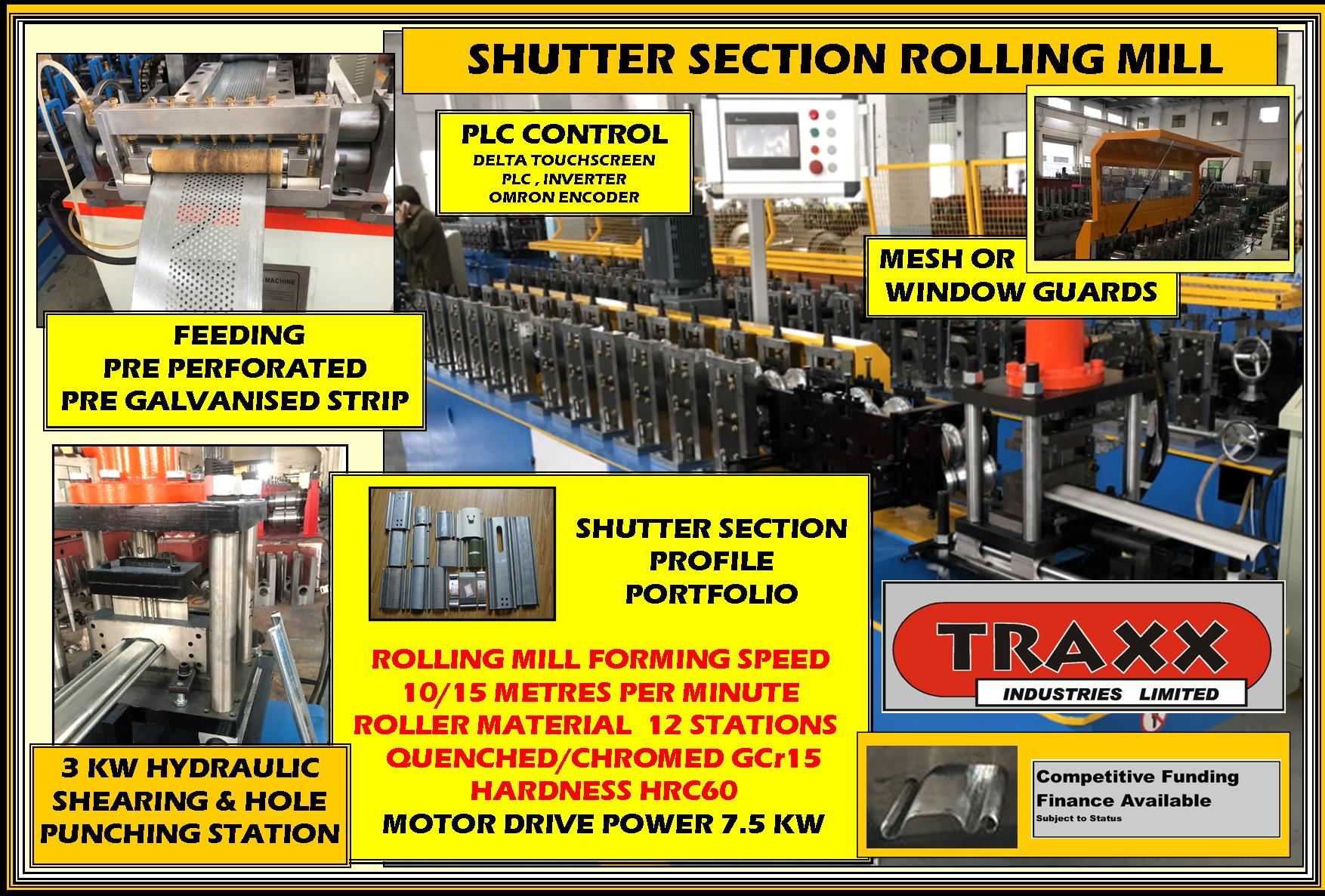

Shutter Door Section Rolling Mills

As well as providing your business with shutter door section rolling mills themselves

We also supply –

A wide range of existing shutter door profile tooling for many existing shutter door profiles.

Alternatively you can advise us of your own shutter door profile design and we can create special

tooling for your business using the specialist software available.

Assembled door sections showing

perforated and standard shutter door sections.

A selection of shutter door sections showing end holes and viewing slots which can be punched during manufacturing.

Fencing Section Rolling Mills

As well as providing your business with the fencing section rolling mills themselves

We can also supply –

A range of existing fencing section tooling for existing fencing profiles.

Alternatively you can advise us of your own fencing profile design and we can create special

tooling for your business using the specialist software available.

Special Section Rolling Mills

We have access to a wide range of special purpose tooling for standard and non standard profiles and can adapt existing chassis to new

tooling with specialist software to design roll tools which are subsequently turned and supplied from high speed CNC lathes.

The economics of cold rolled section technology is well proven with volume sections usually benefiting from conversion from press braking. The yield is industry transforming economics for manufacturers that invest in this capital plant. This results in lower cost end product and better contribution for the manufacturer.

Many successful companies have been established worldwide, initially using one set of roll tools and one mill with the resulting price advantage of end product this brings.

Z & C Section Interchanger Rolling Mills

These highly developed section rolling mills for (C) Channel and Z sections used in typically buildings components, feature the ability to

quick size change between section, enabling a full range of sizes to be produced from this rolling mill investment. As a result many different sizes of ( C) channel or Z section can be made from the same rolls/ rolling mill easily.

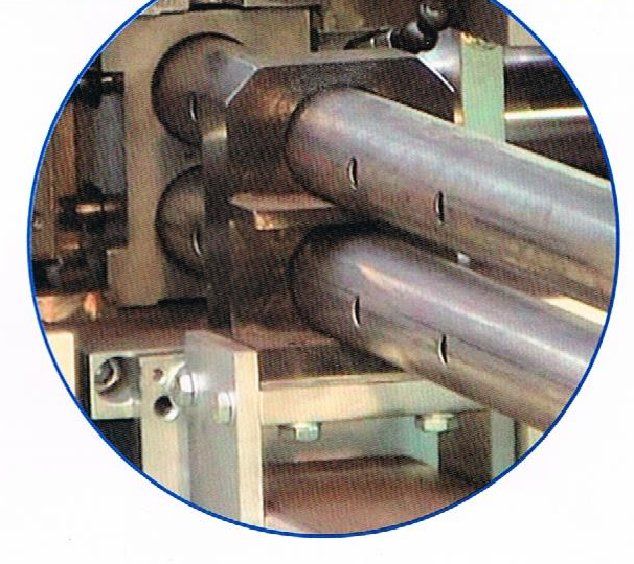

Tube Mills

Tube mills are an extension of cold rolling technology incorporating a welded seam in the manufacturing process. We can supply a wide range of such mills from small to large diameter round tube, to square tube or rectangles and oval tube for example. Applications for these machines can be found throughout industry from car radiator tube for instance to the box section made by large steel manufacturers.

Decoilers

Various sizes of decoilers are available from the company and can be supplied as part of the cold rolling mill or tube mill line typically.

Decoilers can also be supplied separately for use with other machinery such as presses. The picture to the right

shows a hydraulically operated 5 ton decoiler which is typical for heavier coils.

High Speed Section & Tube Punching

We can also punch tubes and section at very high speeds.

The CNC section and tube punching capabilities of the company are very strong with machines and lines we supply among the best of their type in the world.

These can be incorporated in rolling mill lines or used as discrete machine systems, some with very long levels of production autonomy being achieved from some of the bigger machine systems.

The picture on the right shows 2 tubes being punched together on a high speed machine that automatically loads and unloads tube product onto the line. Tube and section can also be punched on more than one face at once with 1,2,3 and 4 face punching possible. Punch tools can be easily changed to allow different sizes and profiles of tube and sections to be punched if this is required and specified at time of order.

Other Types Of Section & Tube Manufacturing Machines Available.

Tube & Pipe Notching PTP-1100 & PTP-1120

As suppliers of the full range of Baileigh Industrial products a dealership now well established since the start of Traxx Industries in 2010,

we also offer CNC controlled hole cutting in tubes using the PTP range of CNC controlled pipe and tube cutters. The units have the ability to cut round holes, slots and notch pipes and tubes from 50 - 300 mm diameter using plasma technology and in bed lengths of 3 metres ( PTP-1100) and 6 metres (PTP 1120) depending on machine size.

Applications for these machines exist in structural steel manufacturing especially. Smaller volume bespoke cutting is possible

with this technology as well as repetitive volumes of steel.

Of course we can also bend tube, notch it and end form with the many ranges of tube benders and associated fabrication plant available through our Baileigh dealership. A good range of roll bend tooling is also stocked in the UK for fast exploitation by fabrication manufacturing business.

RM 40 R CNC 45 RDB 175 RDB 050 HFM 38

CNC Product Feeders

We can also feed product using CNC technology. The simple machine on the right shows a pillar drill being fed with a precisely

controlled adjustable index by a CNC feeder. These machines can also be adapted to feed such machines as horizontal press brakes, ironworkers bandsaws and woodworking machines supplied by the company such as chop saws to provide precision and increase productivity.

PRT – 1878 Feeder

Another machine for this purpose is Baileighs PRT–1878 available through ourselves as dealers. This is a very simple way

Another machine for this purpose is Baileighs PRT–1878 available through ourselves as dealers. This is a very simple way

of increasing productivity and should be considered when volume sales of a discrete product are achieved helping to ensure precision and productivity levels and therefore good contribution from the manufacturing.

The machines can also be used as an adjustable backstop

with a bed length of 2 metres.

Call Traxx Industries Ltd for all the rolling mills and associated equipment you need for your workshop.

We are based in Haverhill

Call: 07963 851 455

Get in touch

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your query.

Please try again later

Share

Tweet

Share

Mail

© 2024. The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.